Dec 17, 2025

Crafting the Future of Hospitality Design: Inside Neil Allen Industries’ Approach to Engineering, Materials, and Custom Fabrication

When great hospitality design comes to life, it’s because vision and execution move in lockstep. Few companies embody this collaboration as seamlessly as Neil Allen Industries, a custom millwork and furniture fabrication studio with nearly four decades of experience and a team that has grown together long enough to speak the same design dialect.

Our co-founder Fiona Sanipelli sat down with Nicole Fulcher, President of Neil Allen Industries, and Brittany Ransburg, Vice President of Inside Sales. Both have spent nearly seven years with the company and worked together even before that. Their tenure speaks volumes: Neil Allen is not a revolving door, it’s a place where expertise is built, preserved, and continuously refined.

What follows is a look inside their process, their insights, and their perspective on the trends reshaping hospitality design today.

Market at EDITION by bonetti/kozerski; custom fabrication by Neil Allen Industries

A Company Built on Continuity and Deep Expertise

Founded in 1985 by Neil Aberman, the company started as a nimble solution for a hospitality project in Miami. After relocating to High Point in 1992, the business expanded into what it is today:

A quasi family-run company with an unusually stable team and a long memory for the craft.

Nicole now leads the company as President, with Neil’s son Jake Aberman serving as Vice President of Operations and engineering lead. Together, they head a team with decades of collective knowledge.

This low turnover is more than a cultural detail, it directly impacts the quality of work:

“Our team has been together so long that we keep a huge amount of experience in-house. We don’t lose our know-how.”

In an industry where staff changes often lead to inconsistent output, Neil Allen’s stability is a competitive advantage designers feel immediately.

The Ritz Carlton Naples; custom furniture by Neil Allen Industries

Custom Work, End to End: “We Know Engineering Through and Through”

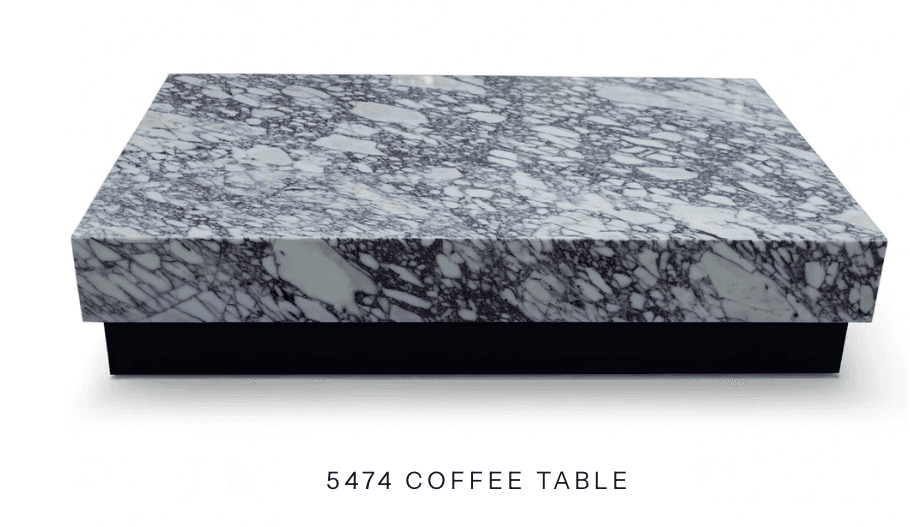

Unlike many manufacturers, Neil Allen Industries does not run a product line. Everything aside from select program tables for Hilton and Marriott is made to order, either in their North Carolina operations or through trusted partners in China and Vietnam. Their sister company, The Stone Resource, fabricates stone in-house, ensuring consistency and quality designers can trust.

But perhaps the most notable shift in recent years is how often designers are handing off the responsibility for engineering the pieces.

“Designers used to send drawings. Now they send an inspo image and dimensions and we take it from there.”

For designers working on fast-paced hospitality projects, this is invaluable. Public space items are almost always the last pieces addressed, often with the tightest timeline and most technical requirements. Neil Allen’s team, including two seasoned project managers and Jake, an engineer - steps in to fill that gap.

The Neil Allen team translates inspiration into buildable reality: structural plans, shop drawings, slab layouts, material selection, and prototype coordination for model rooms.

This level of partnership is more than a service, it’s a relief for designers who don’t want to (and often don’t have time to) solve every technical puzzle alone.

Material Intelligence: Guiding Designers Toward Durability and Beauty

Hospitality design is as much about performance as aesthetics, and the Neil Allen team is candid about what works and what doesn’t, in real-world environments.

Stone in Hospitality: A Love Story With Conditions

Marble is a designer favorite, but as Nicole notes:

“Marble is beautiful, but not the most hospitality-friendly.”

Their team helps guide designers toward smarter solutions depending on placement:

Quartzite for durability

Porcelain slab for restaurant and high-use tables

Sealants or tough-skin treatments for vulnerable stones

Porcelain CNC cuts that mimic mosaic tile and can be inset seamlessly into countertops

They’ve even collaborated with external tile studios like Artaic to bring unique inlay concepts to life.

And, on the far end of the spectrum, they’ve sourced specialized stones directly from Italy, including 90 slabs of fantasy bronze for the Autograph Scottsdale project.

Industry Trends: What’s Showing Up in Hospitality Projects

Neil Allen’s vantage point across hundreds of custom projects gives them a clear pulse on evolving material preferences. Some trends they're seeing:

1. Copper Is Back

Warm, reflective, and timeless, it’s making its way back into public space furniture.

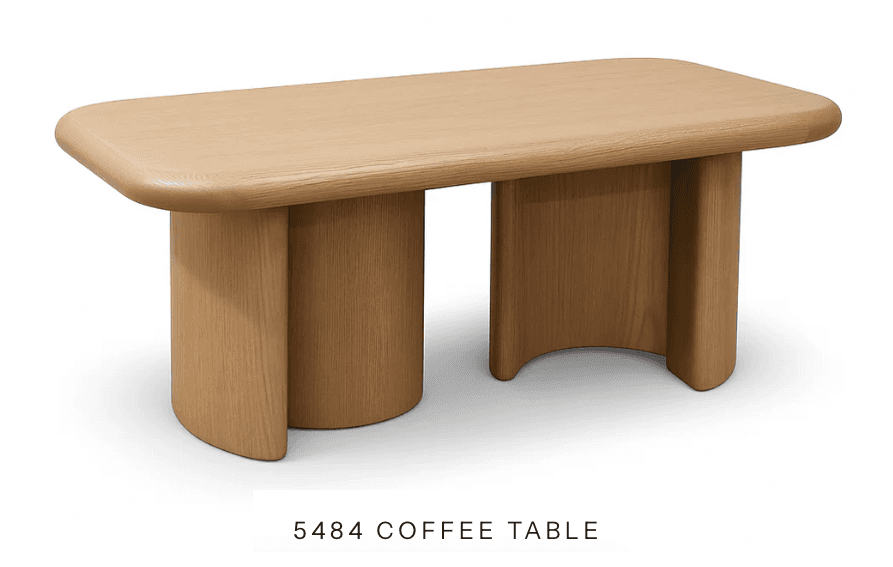

2. Fumed & Flaky Oak Veneers

Flaky oak, in particular, offers depth and figuring similar to spalted maple, adding richness without heaviness.

3. Bullnose Stone Edges

Softened edges are returning, both for safety and for the modern-organic look designers are craving.

4. Porcelain Over Natural Stone

Better durability, lower cost, lighter weight and nearly indistinguishable from real marble. Designers are moving quickly in this direction.

Raffles Boston; custom furniture by Neil Allen Industries

Behind the Design: The Most Outlandish Request Yet

When asked about the most memorable project, Britney didn’t hesitate:

“A designer requested a server station built into a giant stone boulder.”

The task? Source the boulder, carve it, and figure out how to make a multi-ton rock move.

Ultimately, the project didn’t proceed due to cost but the fact that the team seriously explored it reflects their ethos: no idea is too wild to investigate.

Looking Ahead: Growth Powered by Innovation

As new members of the DS Collection, Neil Allen Industries hopes to showcase their materials, finishes, and custom capabilities more directly to designers.

Future priorities include:

Investing further in domestic wood manufacturing capabilities

Continually upgrading equipment for faster fabrication efficiencies

Expanding their in-house engineering

Their focus is simple: support designers better, faster, and with more technical excellence than ever.

DesignSpec Connects Designers With the Details That Matter

At DesignSpec, we believe great design happens when vision and execution work in harmony.

By organizing specifications beautifully and clearly, designers can collaborate more effectively with fabrication partners like Neil Allen, ensuring the final piece reflects both creativity and craftsmanship.

If you’d like more interviews, shop spotlights, or behind-the-scenes fabrication insights, let us know. We love amplifying the makers who shape the spaces we live, work, and gather in.